- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

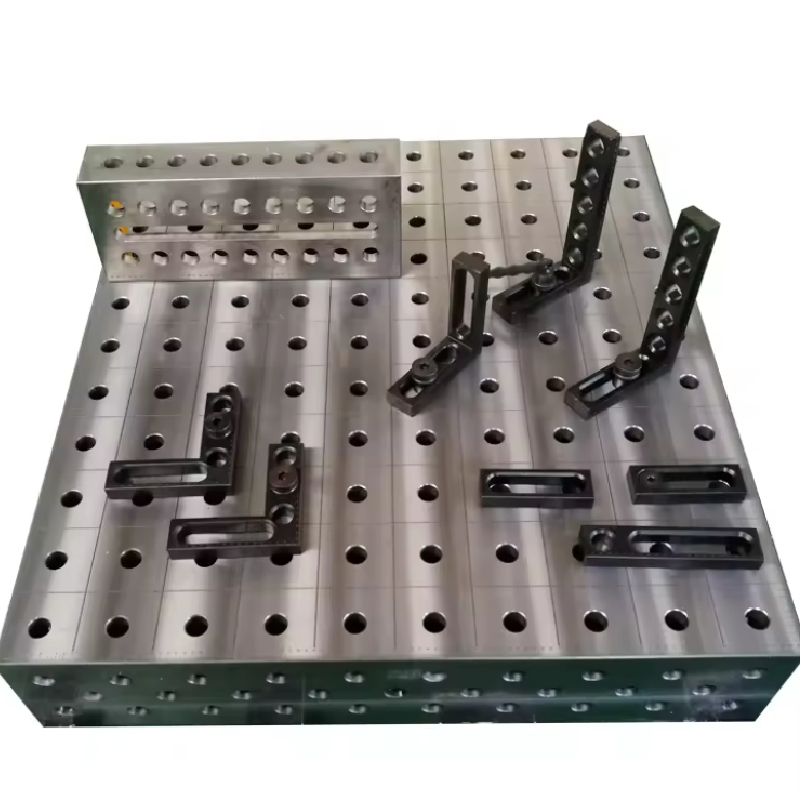

3D welding kplɔ̃ .

Adzɔnuwo ƒe nɔnɔmetata .

Teƒe si wotso:Hebei

Mɔɖegbalẽ:Ƒe 1

Kpekpeɖeŋu si wowɔ ɖe ɖoɖo nu: OEM, ODM

Adzɔnu ƒe Ŋkɔ: Storan

Kpɔɖeŋu xexlẽdzesi:2005

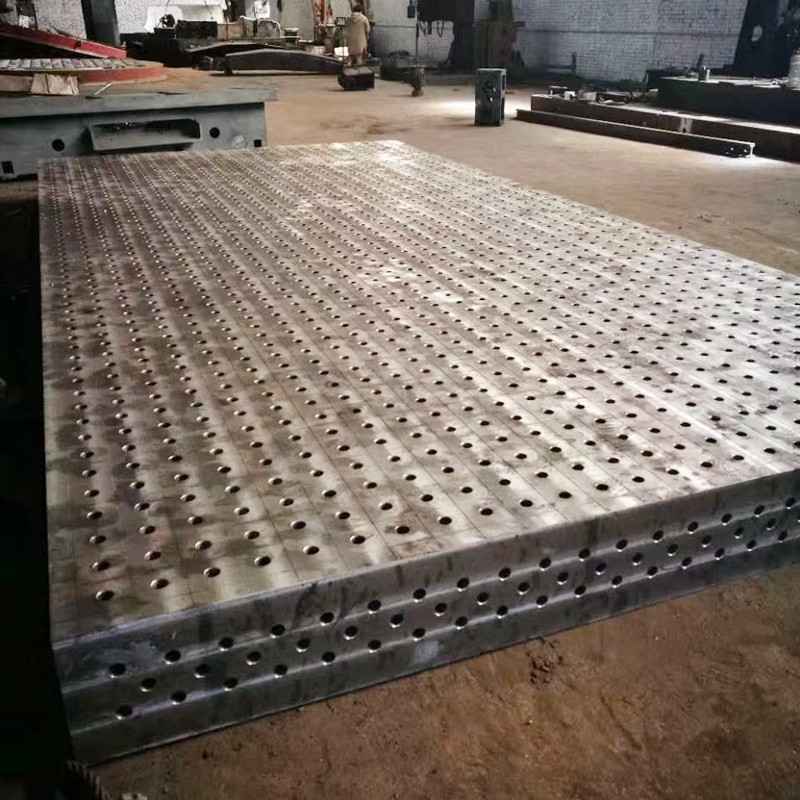

Adzɔnu ƒe Ŋkɔ:3D Flexible Welding Platform Material

Nusiwo wotsɔ wɔe: wotsɔ gayibɔ/ga si wotsɔ ƒo ƒui

Dɔbiagbalẽvi:Dɔwɔƒe

Pore ƒe lolome ƒe mɔɖeɖe:±0.05mm

Surface treatment t:Surface nitriding .

Flatness:0.02mm/1000mm

Roughness:RA1.6-RA3.2.

Dɔwɔwɔ:CNC Machining

Type (Moulding

Ðaseɖigbalẽ (iso9001:2008

Packaging Details (Plywood Aɖaka 3D Welding Table kple kpeɖeŋutɔ OEM HT300 Black Oxide Finish 3D Flexible Welding Table

Selling Units (Nu ɖeka kolia

Nu ɖeka ƒe lolome:100x100x20 cm

Kpekpeme bliboa ƒe kpekpeme:5000 kg

Ɣeyiɣi si woatsɔ awɔ dɔe .

|

Agbɔsɔsɔme (pieces .) |

1 – 100 |

> 100 |

|

Ɣeyiɣi si woatsɔ awɔ dɔe (ŋkekewo .) |

5 |

be woawɔ ɖoɖo ɖe eŋu . |

3D welding kplɔ̃ .

3D Welding Platform nye welding platform deŋgɔ aɖe, si nye nuƒolanɔƒea .

eye woma akpa ene kple do siwo nye 28, siwo wozãna tsɔ wɔa ɖeka kple .

3D flexible fixture, be woaɖo teƒe si woawɔ dɔ le kabakaba kple wo ƒoƒo ɖe wo nɔewo ŋu .

Ele be woatsɔ ga awɔ emae. Viɖe siwo le 3D welding platform ŋue nye dɔwɔwɔ nyuie ŋutɔ, .

Nusiwo sɔ pɛpɛpɛ ŋutɔ, kple ga home sue aɖe. 3D welding tooling systems ƒe hatsotso aɖe ate ŋu anye .

Na asisiwo ƒe welding ƒe akpawo katã naɖi kɔ na wo.

Adzɔnuwo ƒe nɔnɔmetata .

|

3D welding kplɔ̃ ƒe nɔnɔmetata ƒe agbalẽvi . |

|||||

|

D28 ƒe ƒuƒoƒo . |

D16 ƒe ƒuƒoƒo . |

||||

|

Xexlẽdzesiwo . |

Specification . |

kpekpeme |

Xexlẽdzesiwo . |

Specification . |

kpekpeme |

|

JM-D28-1010 |

1000*1000*200 |

380KG |

JM-D16-1005 |

1000*500*100 |

70KG |

|

JM-D28-1212 |

1200*1200*200 |

430KG |

JM-D16-1010 |

1000*1000*100 |

120KG |

|

JM-D28-1015 |

1000*1500*200 |

450KG |

JM-D16-1208 |

1200*800*100 |

120KG |

|

JM-D28-1020 |

1000*2000*200 |

600KG |

JM-D16-1212 |

1200*1200*100 |

170KG |

|

JM-D28-1224 |

1200*2400*200 |

850KG |

JM-D16-1015 |

1000*1500*100 |

180KG |

|

JM-D28-1520 |

1500*2000*200 |

880KG |

JM-D16-1515 |

1500*1500*100 |

270KG |

|

JM-D28-1530 |

1500*3000*200 |

1300KG |

JM-D16-1020 |

1000*2000*100 |

250KG |

|

JM-D28-2030 |

2000*3000*200 |

1800KG |

JM-D16-1224 |

1200*2400*100 |

350KG |

|

JM-D28-2040 |

2000*4000*200 |

2700KG |

|

|

|

Adzɔnuwo ƒe wɔwɔfia .

Woate ŋu adzra akpawo ɖo le wò tiatia siwo gbɔna la megbe .:

1, Dɔwɔnu siwo woatsɔ ado alɔe: U-nɔnɔme cube case, L-nɔnɔme cube case, dzogoe dzi kpekpeɖeŋu, kple dzogoedzidzenu

2, spare parts for locating .:

3, dɔwɔnu siwo woatsɔ abla wo ahaɖɔ wo ɖo .

4, spare akpawo na ʋuʋu dɔwɔwɔ piece .

5, Dɔwɔnu Siwo Wotsɔ Kpena Ðe Ame Ŋu .

3D welding kplɔ̃ 1.2×2.4 1×2 1.5×3 2x4m le nudzraɖoƒe gayibɔ kplɔ̃ kple fixture kplɔ̃ .

- - Dimensions:1000X1000mm-2000X4000mm

- - Dɔwɔwɔ ƒe akpa atɔ̃ Woate ŋu atsɔ teƒe si woatsɔ akpɔ teƒe si wole la ade. Woate ŋu akeke ɖe enu hã to eƒe dɔwɔƒe atɔ̃awo dometɔ ɖesiaɖe dzi.

- - Woma eƒe nusi wotsɔ wɔe la ɖe: gakpo siwo wotsɔ wɔa xɔtunuwoe (Q345) kple kplɔ̃ siwo wotsɔ ƒoa nuwoe (HT300) me.

- - Eƒe do ƒe didime ma ɖe: D28 Series kple D16 Series me.

- - Diagonal grid: D28 nye 100 * 100mm; D16 nye 50 * 50mm.

Ŋutinuwo

Kpekpeɖeŋunana .: Afɔwo, gakpo ƒe xɔtunu, kple tsi si wotsɔna kɔa amee, le nudidi si nye be woawɔe nu.

3D welding ƒe mɔ̃a nye xexeame katã ƒe nusi wotsɔna ƒoa nu ɖe nu ŋu si wowɔ koŋ na nusiwo wotsɔ wɔa nuawoe wɔwɔ; Wozãnɛ hena welding bɔbɔe, asitɔtrɔ le nɔnɔmewo ŋu, kple geɖe siwo to vovo tso blema welding mɔnu siwo wozãna tsã gbɔ.

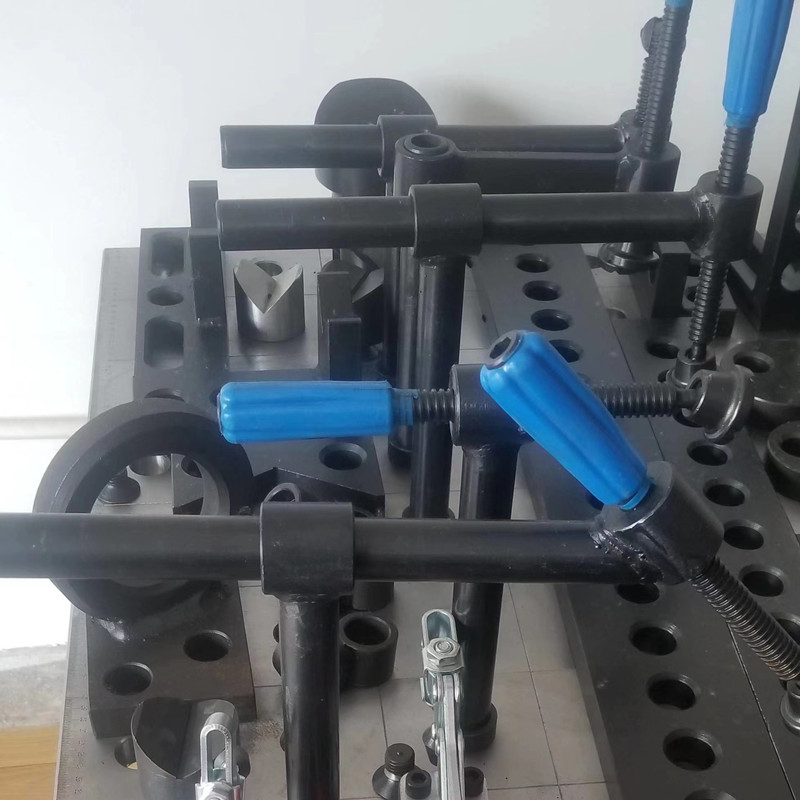

Etɔ̃-dimensional do ɖoɖo ƒokpli flexible welding dɔwɔwɔ dɔwɔnuwo.

Dzidzeme etɔ̃ .: tsi tre ɖi na mɔfiame etɔ̃. Zi geɖe la, fixtures nyea didime kple transverse si me mɔfiame siwo le tsitrenu mele o. Mɔfiame eve le nuƒolanɔƒea ŋu, eye woate ŋu azã go eneawo atsɔ aɖoe ɖe tsitrenu, si ana woawɔ akpa etɔ̃ ƒe ƒuƒoƒo.

Do ƒe ɖoɖo .: Nusi koŋ le fixture sia ŋue nye be tso nuƒolanɔƒea dzi va ɖo kpeɖeŋutɔawo dzi la, do siwo wozãna ɖaa siwo me ka siwo wozãna tsã alo T-slotwo mele o la li. Ne wotsɔe kpe ɖe ʋuƒo siwo wotsɔna ƒoa nu kabakaba ŋu la, woate ŋu awɔ kpekpea kabakaba eye wòanɔ bɔbɔe wu, eye woate ŋu aɖo teƒe si wòle.

Nuƒoƒu: Esi wònye be wowɔ kpeɖeŋutɔawo katã do ŋgɔ ta la, woate ŋu aƒo wo nu ƒu ahawɔ asitɔtrɔ le wo ŋu le nusi wowɔ ƒe hiahiãwo nu.

Asitɔtrɔ le nɔnɔmewo ŋu .: Le dɔwɔwɔ siwo míeyɔ ɖe etame me la, dɔwɔnu bliboa ate ŋu atrɔ le tɔtrɔ siwo le nusi wowɔ me nu. Fixtures ƒe hatsotso aɖe ate ŋu akpɔ nu geɖe alo nu gbogbo aɖewo ƒe nuhiahiãwo gbɔ, si ana adzɔnuwo ŋuti numekuku kple ŋgɔyiyi kple dodokpɔ wɔwɔ ƒe ɖoɖoa nadzi ɖe edzi ŋutɔ, si ana amewo ƒe ŋusẽ, ŋutilãmenunɔamesiwo, kple gazazã geɖe nanɔ anyi (nu siwo le nutoa me xɔlɔ̃wɔwɔtɔe kple nusiwo me carbon mesɔ gbɔ ɖo o).

Welding .: Adzɔnu sia nye xexeame katã ƒe nusi woɖo koŋ na nusiwo wotsɔ ga wɔe wɔwɔ; Wozãnɛ hena welding bɔbɔe, asitɔtrɔ le nɔnɔmewo ŋu, kple geɖe siwo to vovo tso blema welding mɔnu siwo wozãna tsã gbɔ.

Nudidi vevi siwo hiã na anti-rust primer le 3D welding platform dzi enye: adhesion nyui aɖe ɖe casting la ƒe go ŋu, anti rust ƒe dɔwɔwɔ nyuie, adhesion nyui aɖe ɖe supper layer of paint ŋu, kple xɔtutu kple nudzraɖoƒe bɔbɔe.

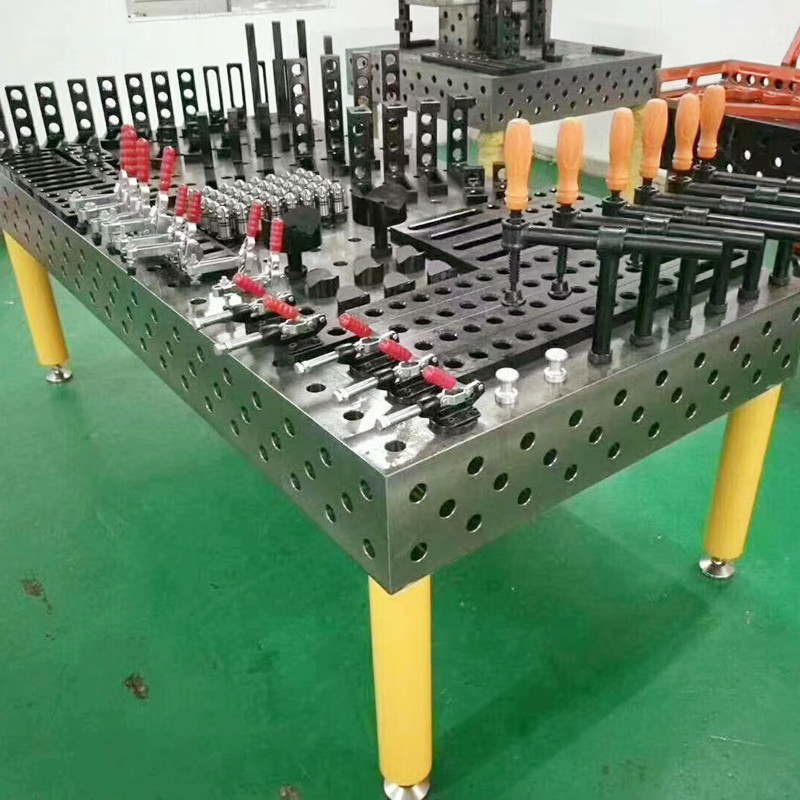

Top features be woadi le 3D welding kplɔ̃ dzi .

Ne èle 3D welding kplɔ̃ tiam la, ele vevie be nàbu nu vovovo siwo doa ŋusẽ dɔwɔwɔ kple nuwɔwɔ pɛpɛpɛ ŋutɔ le wò welding dɔwo me ŋu. 3D welding kplɔ̃ si le nyonyome nyuie ate ŋu ana vovototoa katã nasu ame si le emetsonu nyuitɔ kekeake gbɔ ɖoɖo me. Nusiwo le ŋgɔ wue nye esi be woadi .:

1. Xɔtutu sesẽ: Ele be woatsɔ nusiwo ƒe nyonyome de ŋgɔ siwo te ŋu nɔa te ɖe agba kpekpewo kple welding ƒe dɔwɔwɔ ƒe sesẽme nu la awɔ 3D welding kplɔ̃ sesẽ aɖe. Di kplɔ̃ siwo wotsɔ gakpo alo gayibɔ si nɔa anyi didina wɔ, si ana nànɔ agbe didi eye wòli ke.

2. Modularity: Ŋutete si le asiwò be nàtrɔ asi le wò ɖoɖoa ŋu ahawɔ asitɔtrɔ le eŋu la le vevie ŋutɔ. Modular 3D welding table ɖe mɔ be woawɔ add-ons kple accessories vovovowo ƒe ƒoƒo ɖekae, si ana nàte ŋu atrɔ asi le wò dɔwɔƒe ŋu wòasɔ ɖe dɔ tɔxɛ aɖewo nu, eɖanye aɖaŋu sue siwo me kɔ alo takpekpe gãwo o.

3. Precision Machining: Be woaɖo nyateƒetoto gãtɔ kekeake gbɔ la, ele be woatsɔ mɔ̃ awɔ anyigba kple teƒe siwo le 3D welding kplɔ̃a dzi pɛpɛpɛ. Di kplɔ̃ siwo naa grid ƒe nɔnɔme si me do kple do siwo dome didi nyuie le, siwo naa dɔwɔwɔ ƒe akpa siwo le dedie kple woƒe nɔƒewo nɔa bɔbɔe.

4. Clamping Options versatile clamping: Clamping solutions nyuiwo le vevie ŋutɔ na kakaɖedzi be li ke le welding ƒe ɖoɖoa me. Ele be 3D welding kplɔ̃ nyui aɖe nana teƒe vovovo siwo woatsɔ aɖoe kple nusiwo wotsɔna blaa nue, si ana woate ŋu awɔ ɖoɖo siwo te ŋu trɔna bɔbɔe eye woalé nu vovovowo ƒe nɔnɔme kple lolomewo ɖe te dedie.

5. Nusiwo sɔ kple nusiwo wotsɔna ƒoa nuwoe: Kpɔ egbɔ be 3D welding kplɔ̃ si nàtia la sɔ kple fixturing system vovovowo. Ne wowɔ ɖeka sia la, ana wò ŋutete be nàwɔ ɖoɖo siwo wowɔ ɖe ɖoɖo nu kabakaba eye wòawɔ dɔ nyuie la nanyo ɖe edzi, si ana nàkpɔ ɣeyiɣi geɖe wu eye wòana dɔwɔwɔ nadzi ɖe edzi.

6. Anyigbadzidɔwɔwɔ: Anyigbadzinu si te ŋu nɔa te ɖe ɖiƒoƒo kple vuvu nu le vevie ŋutɔ le afisi wowɔa nu le. Di kplɔ̃ siwo dzi wotsɔ nusiwo tsia tre ɖe nu ŋu ƒe nutrenuwo alo nusiwo wotsɔ wu enui siwo kpena ɖe ame ŋu be wòalé dɔwɔwɔ ƒe akpa si le dzadzɛ me ɖe asi eye nàna kplɔ̃a ƒe agbenɔƒe nadidi ɖe edzi.

Viɖe siwo le 3D welding table zazã me hena dɔwɔwɔ pɛpɛpɛ .

Le ga wɔwɔ ƒe xexeame la, nusiwo sɔ pɛpɛpɛ kple woƒe nuwɔwɔ pɛpɛpɛ gbɔ ɖoɖoe nye nu vevitɔ kekeake na dɔ siwo akpɔ dzidzedze. Dɔwɔnu nyui siwo li na welders dometɔ ɖekae nye 3D welding kplɔ̃ si sɔ pɛpɛpɛ. Menye ɖeko dɔwɔnu vevi sia nana dɔwɔwɔ nyona ɖe edzi ko o, ke enaa dɔ si wowɔ vɔ la ƒe nyonyome nyona ɖe edzi ŋutɔ.

Wotrɔ asi le 3D welding kplɔ̃ si sɔ pɛpɛpɛ ŋu kple ɖoɖo sesẽ aɖe si ɖea mɔ na ɖoɖo siwo woate ŋu atrɔ asi le siwo wowɔ ɖe ɖoɖo nu ɖe dɔ ɖesiaɖe ƒe nudidi tɔxɛwo nu. Zi geɖe la, wotsɔa nu siwo le nyonyome nyuie wɔa anyigba la, si wɔnɛ be wònɔa anyi didina eye wòli ke le welding dɔwɔwɔwo me. Liliɖe sia ate ŋu axe mɔ ɖe ga ƒe akpa siwo ŋu wole dɔ wɔm le la ƒe tsɔtsɔ alo woƒe tɔtɔ nu, si le vevie ŋutɔ be woalé dzidzenu deŋgɔwo me ɖe asi.

Viɖe ɖedzesi bubu si le 3D welding kplɔ̃ si sɔ pɛpɛpɛ zazã me enye jigs kple fixture deŋgɔ siwo wòate ŋu awɔ. T-slot alo do siwo nana welders te ŋu blaa akpa aɖewo nyuie la le kplɔ̃ siawo dometɔ geɖe ŋu. Nɔnɔme sia le vevie na dɔ siwo le akpa vovovowo me, afisi ɖoɖowɔwɔ nyuitɔ me léle ɖe asi le vevie ŋutɔ le. Esia wɔnɛ be afɔku si le eme be woawɔ nu ɖe ɖoɖo nu kple vodadawo dzi ɖena kpɔtɔna ŋutɔ, si wɔnɛ be woate ŋu awɔ weld siwo le dzadzɛ eye wowɔa nu pɛpɛpɛ.

Gawu la, 3D welding kplɔ̃ si sɔ pɛpɛpɛ zazã ate ŋu ana dɔwɔwɔ ƒe ɖoɖo nanɔ bɔbɔe eye wòaɖe ɣeyiɣi si wozãna ɖe dɔ ɖesiaɖe ŋu dzi akpɔtɔ. To dɔwɔƒe si woɖo ɖi si ŋu wowɔ ɖoɖo ɖo eye wòwɔa dɔ nyuie nana me la, Welders ate ŋu alé fɔ ɖe woƒe dɔa ƒe nuwɔwɔ kple mɔ̃ɖaŋununya ƒe akpawo ŋu wu tsɔ wu be woalé fɔ ɖe ɖoɖoa ŋu. Dɔwɔwɔ nyuie ƒe dzidziɖedzi sia hea dɔwɔwɔ ƒe agbɔsɔsɔ si lolo wu vɛ eye mlɔeba la, viɖekpɔkpɔ nyona ɖe edzi na dɔwɔƒewo.

Le nyataƒoƒo me la, gadede asi na 3D welding kplɔ̃ si sɔ pɛpɛpɛ nye fefetrɔla na welder dɔwɔla ɖesiaɖe si le didim be yeadzi yewoƒe asinudɔwɔwɔ ɖe edzi. Esi wònye be ŋutete le esi be wòana liƒo, atrɔ asi le eŋu, eye wòawɔ dɔ nyuie ta la, enye dɔwɔnu vevi aɖe si doa alɔ welding dɔ si le ɖoɖo nyui nu eye wòdea pɛpɛpɛ. Eɖanye eŋutinunyala bibi alo nu yeye le welding field me o, 3D welding kplɔ̃ zazã si sɔ pɛpɛpɛ la ado wò dɔwo ɖe dzi ɖikekemanɔmee ɖe ɖoƒe si kplɔe ɖo dzi.

Core Functions kple dɔwɔƒewo ƒe dɔwɔwɔ ƒe asixɔxɔ si le 3D welding kplɔ̃wo ŋu .

Storaen ƒe 3D welding kplɔ̃wo ɖɔa pɛpɛpɛ kple dɔwɔwɔ nyuie le dɔwɔƒewo ƒe welding wɔwɔ me, subɔna abe versatile modular platforms si wowɔ be woawɔ streamline workpiece positioning, fixture integration, kple multi-axis welding dɔwɔwɔwo. Abe ŋgɔdola na welding wɔwɔ kplɔ̃wo, míetsɔa egbɔkpɔnu siwo ƒoa ƒu sesẽ, ɖoɖo siwo woate ŋu atrɔ asi le, kple nyateƒetoto si woate ŋu agbugbɔ awɔ—essential na egbegbe adzɔnuwo wɔwɔ ƒe nɔnɔme siwo bia zero-defect welding me tsonu.

Teƒe si woɖoa nuwo ɖo pɛpɛpɛ le nu vevitɔa me .

Le míaƒe 3D welding kplɔ̃ ƒe nɔnɔme ƒe dzime la, do siwo wotsɔ mɔ̃ wɔ pɛpɛpɛ ƒe akpa atɔ̃ (D28 alo D16, siwo kplɔ wo nɔewo ɖo), si wɔnɛ be woate ŋu atsɔ klatsawo, dzogoewo, kple nusiwo wotsɔna blaa nu ɖe wo nɔewo dzi kple axadzinu eneawo katã ƒe akpa siwo le etame la kpena ɖe wo nɔewo ŋu. Grid ɖoɖo sia (100x100mm alo 50x50mm dometsotso) kpɔa egbɔ be teƒe ƒe nyateƒetoto le ±0.05mm me, si ɖea akɔntabubu ɖa le akpa siwo sesẽ abe ʋu ƒe chassis frames, aerospace brackets, alo heavy-duty machine parts ene me. Nusi do tso emea? Welding setup si woate ŋu agbugbɔ awɔ si ɖea dodokpɔ kple vodada ƒe asitɔtrɔwo dzi kpɔtɔna 60%, si le vevie ŋutɔ na mass production afisiwo mewɔa ɖeka o.

Modular flexibility na nuwɔwɔ vovovowo ƒe hiahiãwo .

Míaƒe welding fab kplɔ̃wo tsina nyuie le tɔtrɔ ɖe nɔnɔmewo ŋu me .:

Multi-Platform Integration: Woate ŋu atsɔ gavi siwo wotsɔna ƒoa nu kabakaba awɔ dɔ siwo keke ta (1000x1000mm vaseɖe 2000x4000mm) atsɔ awɔ dɔ siwo keke ta na dɔ siwo lolo akpa—siwo sɔ nyuie na tɔdziʋututu alo agblemenukuwo ƒe ƒuƒoƒo.

Dɔwɔnu-manɔmee fixture tɔtrɔwo: sɔ kple geɖe welding accessories (U-blocks, T-slots, magnetic clamps), kplɔ̃a ɖe mɔ be woawɔ ɖoɖo kabakaba le dɔ vovovowo dome, cut fixture setup time to 50% ne wotsɔe sɔ kple dekɔnu fixed-position kplɔ̃wo.

Agba kpekpewo ƒe ŋutete: wotu tso HT300 gayibɔ alo Q345 gakpo kple ribbed understructure, kplɔ̃ siawo te ŋu nɔa te ɖe agba siwo meʋãna o vaseɖe 2700kg nu, si doa alɔ dɔwɔƒe ƒe akpa gãtɔwo gɔ̃ hã si me ʋuʋudedi mele o—ele be woatsɔe na excavator arm welding alo crane structure fabrication.

Dɔwɔƒewo ƒe Dɔwɔwɔwo: Afisiwo wowɔa nu pɛpɛpɛ ɖo la doa go dɔwɔwɔ nyuie .

Ʋuwo Wɔwɔ .

Zã abe welding fabrication kplɔ̃ na ʋu ƒe ŋutilã ƒe xɔtunuwo ƒoƒo ƒu, si ana spot welds nasɔ ɖe ±0.1mm me be woaɖo OEM ƒe nyonyome ƒe dzidzenuwo gbɔ. Anti-spatter coating option kpɔa anyigba la ta tso welding gbeɖuɖɔwo me, si kekea subɔsubɔ ƒe agbenɔƒe ɖe enu le gbeɖiɖi gã siwo wowɔna me.

Yamenutome & Takpɔkpɔ .

Vevie na wɔwɔ aluminum alloy xɔtuɖoɖowo (le kpɔɖeŋu me, yameʋu ƒe mɔ̃ ƒe to), afisi kplɔ̃a ƒe dzoxɔxɔ ƒe liƒo (kekeɖenu suetɔ kekeake le welding dzoxɔxɔ me) kple gbadzaa (0.02mm/1000mm) xea mɔ na didime ƒe teteɖeanyi si ate ŋu agblẽ yameʋuɖoɖo ƒe dedienɔnɔ me.

Mɔ̃ sesẽwo & dɔwɔnuwo .

Go-to solution na welding bulldozer frames alo industrial pump casings, akpe ɖe eƒe sesẽ xɔtutu kple modular atsyã si xɔa odd-nɔnɔme dɔwɔwɔwo to custom fixture installations.

Nusita Storaen 3D welding kplɔ̃wo kplɔa mɔa .

Beyond core functions, míaƒe kplɔ̃wo ƒe nɔnɔme .:

Surface finish excellence: Anyigba ƒe anyigba (RA1.6-RA3.2) kpɔa egbɔ be fixture ƒe ʋuʋu le bɔbɔe eye wowɔe pɛpɛpɛ, esime nitriding dɔdamɔnu si woate ŋu awɔ la doa ŋusẽ vuvu ƒe tsitretsitsi le abrasive welding nɔnɔme me.

Xexeame Katã ƒe Dzidzenu ƒe Sedziwɔwɔ: Woɖo kpe edzi na ISO 9001 kple JB/T7974-99, míaƒe 3D welding kplɔ̃wo ɖo dukɔwo dome nuwo wɔwɔ ƒe dzidzenuwo ƒe didi sesẽwo gbɔ, si naa susu ƒe akɔdzeanyi le liƒodzidɔwo me.

Do wò welding ƒe ɖoɖoa ɖe dzi kple Storaen .

Eɖanye be èhiã na FAB kplɔ̃ sue aɖe si wotsɔ welding wɔ na prototyping alo 3D welding table gã aɖe na mass production o, Storaen’s solutions naa nusiwo sɔ pɛpɛpɛ, woƒe anyinɔnɔ didi, kple asitɔtrɔ le nɔnɔmewo ŋu si hiã be woanɔ ŋgɔ le egbegbe nuwo wɔwɔ me. To ɖoɖowɔɖi ƒe ɣeyiɣi dzi ɖeɖe kpɔtɔ, fixture ƒe sɔsɔ dzi ɖeɖe kpɔtɔ, kple kakaɖedzi be woate ŋu agbugbɔ awɔ nu pɛpɛpɛ me la, míaƒe kplɔ̃wo trɔa welding tso mɔfiamegbalẽ, vodada-bɔta ƒe dɔwɔwɔ me wòzua dɔwɔwɔ ƒe ɖoɖo si wowɔ le ɖoɖo nu, si naa ŋusẽ wò ƒuƒoƒoa be wòatu nyuie wu, kabakaba, eye kakaɖedzi si mesɔ o nasu asiwò.

Kpekpeɖeŋunaɖoɖowo kple egbɔkpɔnu siwo wowɔ ɖe ɖoɖo nu na 3D welding kplɔ̃wo .

Storaen ƒe 3D welding kplɔ̃wo kpe ɖe accessory system si me kɔ kple esiwo wowɔ ɖe ɖoɖo nu siwo wowɔ ɖe ɖoɖo nu, siwo wowɔ be woadzi versatility, precision, kple adaptability ɖe edzi na welding fabrication hiahiã ɖesiaɖe. Eɖanye akpa siwo woɖo ɖi na ɖoɖo kaba alo tɔtrɔ siwo wowɔ ɖe ɖoɖo nu na dɔ tɔxɛwo wɔwɔ o, míaƒe nunanawo trɔa wò welding fabrication kplɔ̃a wòzua dɔwɔƒe tɔxɛ aɖe ŋutɔ—si wowɔ be wòawɔ ɖe egbegbe adzɔnuwo wɔwɔ ƒe didi vevie gbɔ.

Modular accessory ecosystem na ɖekawɔwɔ si me kuxi aɖeke mele o .

Míaƒe plug-and-play accessories doa ŋusẽ wò welding fab kplɔ̃a ƒe dɔwɔwɔ, si wɔnɛ be ɖoɖowɔwɔ ƒe tɔtrɔ kabakaba kple dɔwɔwɔ nyuie wu:

Kpekpeɖeŋu & Leveling Dɔwɔnuwo: Trɔ asi le gakpo afɔwo kple anti-vibration pads kpɔa egbɔ be ɖoɖo si li ke le fiase ƒe anyigba siwo mesɔ o, esime hadrolik kɔkɔ ɖoɖowo (100–500mm kɔkɔme dometsotso) na ergonomic teƒe na overhead alo sesẽ be welds.

FixTuring & Clamping Solutions: Magnetic clamps, toggle clamps, kple U-blocks ƒe hatsotso aɖe (si sɔ kple D28/D16 Hole Systems) De dɔwɔwɔ ƒe akpa siwo ƒe lolome kple lolome katã le dedie, kple mɔ̃ siwo woɖena kabakaba si ɖea fixture installation ɣeyiɣi dzi kpɔtɔna 40%. Angled brackets (0–90° adjustable) kple square siwo sɔ pɛpɛpɛ kpena ɖe multi-axis ƒe ɖoɖowɔwɔ ŋu, si le vevie ŋutɔ na assemblies siwo sesẽ abe robot arms alo aerospace trusses ene.

Dedienɔnɔ & Takpɔkpɔ ƒe kpeɖeŋutɔwo: Anti-spatter coatings (si wotsɔ kpe ɖe kplɔ̃dzinuwo ŋu) kple splash guard siwo woate ŋu aɖe ɖa la ɖea gbeɖuɖɔwo ƒe ƒuƒoƒo dzi kpɔtɔna, esime dzoxɔxɔ-mate ŋu nɔa te ɖe mats ta kpɔa grid ɖoɖoa ta be woagaƒo ka na wo ɣeyiɣi didi o—si keke kplɔ̃a ƒe subɔsubɔ ƒe agbenɔƒe ɖe enu le nuto siwo me wowɔa nu geɖe le me.

Egbɔkpɔnu Siwo Wowɔ Ðe Ðoɖo Nu: Wotrɔ asi le wò nukpɔkpɔ ŋu .

Tailored Dimensions & Configurations .

Le dzidzenu ƒe lolomewo (1000x1000mm va ɖo 2000x4000mm) megbe la, míewɔa 3D welding kplɔ̃wo le didime, kekeme, kple kɔkɔme siwo wowɔ ɖe ɖoɖo nu me—siwo dometɔ aɖewoe nye mɔ̃ siwo lolo akpa (vaseɖe 5000x3000mm) na dɔwɔƒewo ƒe dɔwo wɔwɔ. Nɔnɔme siwo mele dzogoe ene me o (gogoewo, siwo le abe L ene) kple teƒe siwo wotu ɖe eme la sɔ na mɔ̃ tɔxɛwo alo robot siwo wowɔna le wo ɖokui si, si ana nàkpɔ egbɔ be wowɔ ɖeka kple wò nuwɔwɔ ƒe mɔ̃ si me kuxi aɖeke mele o.

Nusiwo wotsɔ wɔa nu pɛpɛpɛ ƒe nɔnɔmewo .

Hole System Customization: Trɔ asi le do ƒe dometsotso ŋu (le kpɔɖeŋu me, 75x75mm na hybrid grids) alo nàgblɔ metrik/fiaɖuƒe ka ƒomeviwo (M12, 1⁄2”-13 UNC) be woasɔ kple fixture siwo li xoxo, si ɖea adapter platewo ƒe hiahiã ɖa.

Surface treatments: Tia tso anyigba ƒe nuwuwu (RA1.6 na standard use) alo super-finished surfaces (RA0.8 na metrology-grade alignment), kple nitriding tiatia (HV900+) be nàdo sesẽ eye woatsi tre ɖe abrasive wear ŋu le kpekpe-dɔdasiwo me.

Tɔtrɔ siwo wowɔ le dɔwɔƒewo ŋu koŋ .

Ʋu: Integrated T-Slots na conveyor belt alignment, si sɔ nyuie na ʋu ƒe akpa si wotsɔna ƒoa ʋu ƒe akpa siwo zɔna kabakaba.

Yamenutome: Non-magnetic gakpo si mexɔ dzo o ƒe nusiwo wotsɔ de eme be woaxe mɔ ɖe nutete kple sensitive NDT (non-destructive dodokpɔ) dɔwɔnuwo le aluminum alloy welding.

Ƒumelã: Epoxy-si wotsɔ bla ɖe ete hena xɔxlɔ̃ ƒe tsitretsitsi le dzetsi ƒe nɔnɔmewo me, si wotsɔ kpe ɖe dzogoedzikpe siwo ŋu wodo ŋusẽe ŋu hena ƒuta rig ƒe akpawo wɔwɔ.

Trɔtrɔ kabakaba & Xexeame Katã ƒe Kpekpeɖeŋu .

Stock Accessories: Klam, afɔwo, kple dɔwɔnu siwo wotsɔna ƒoa nuwoe ƒe akpa gãtɔ ɖoa wo ɖe gaƒoƒo 24 me, si wɔnɛ be ɣeyiɣi suetɔ kekeake si woatsɔ atrɔ asi le wo ŋu la nɔa anyi hena asitɔtrɔ le wo ŋu.

Wotsɔ kplɔ̃ɖoɖo siwo wowɔ ɖe ɖoɖo nu: wotsɔ kplɔ̃ siwo wowɔ ɖe ɖoɖo nu (siwo menye esiwo ƒe nɔnɔme sesẽ o) ɖo ɖe wo le ŋkeke 15–20 me, kple mɔ̃ɖaŋununya ƒe kpekpeɖeŋu si woɖo ɖi be woatsɔ atrɔ asi le nɔnɔmetatawo kple nuwo tiatia ŋu (le kpɔɖeŋu me, gakpo si mexɔ dzo o na nuɖuɖu ƒe dzesidewo).

Ðaseɖigbalẽ ƒe nyonyome: 3D welding kplɔ̃ siwo katã wowɔ ɖe ɖoɖo nu la wɔa flatness dodokpɔ sesẽ (0.02mm/1000mm) kple agbatsɔtsɔ ƒe kpeɖodzi, si kpe ɖe ISO 9001-sedede ƒe akɔntabubu ŋuti nyatakakawo ŋu hena nyonyomedzikpɔkpɔ si woate ŋu akpɔ.

Ʋu wò welding fab kplɔ̃a ƒe ŋutete bliboa .

Le Storaen ƒe kpeɖeŋutɔɖoɖowo kple egbɔkpɔnu siwo wowɔ ɖe ɖoɖo nu ta la, wò welding fabrication kplɔ̃a va zua nusi wu dɔwɔkplɔ̃ ko—enye mɔnu si woate ŋu akeke ɖe enu na nu yeyewo dodo ɖe ŋgɔ. Eɖanye be èhiã akpa siwo mele asi me o hena viɖekpɔkpɔ enumake alo 3D welding kplɔ̃ si wowɔ ɖe ɖoɖo nu bliboe na dɔ si woawɔ le anyigba dzi, míaƒe ƒuƒoƒoa ƒoa mɔ̃ɖaŋununya ƒe nunya kple adzɔnuwo wɔwɔ ƒe ablaɖeɖe nu ƒu be woatsɔ akpɔ egbɔkpɔnu siwo sɔ kple wò ŋutega. Do wò welding dɔwɔwɔwo ɖe dzi kple accessories siwo trɔna ɖe nɔnɔmewo ŋu eye wotrɔa asi le wo ŋu siwo trɔna—elabena le wo wɔwɔ me la, pɛpɛpɛ nyea nusianu, eye lolome ɖeka meɖia wo katã gbeɖe o.

Adzɔnuwo me nyawo .

Nusi wozãna zi geɖe be woatsi tre ɖe ke ŋue nye ami ƒe amadede. Dzɔdzɔme aŋɔ ƒe amadede. Asphalt ƒe amadede. Phosphating paint, etc. Woƒe dɔwɔwɔ kple wo zazã ƒe didime to vovo. Wokɔ agba gbadzɛ si wotsɔ ga wɔe la ŋu. Ne èto ɖaseɖiɖidɔa me vɔ la. Zi geɖe la, wotsɔa anti rust paint dea anyigba siwo wometsɔ lãmi wɔe o alo nusiwo katã le edzi la dzi. Ne èle dɔ wɔm la, ele be woase egɔme nyuie be le plate-gbadzɛwo tiatia kple wo wɔwɔ me la, zi geɖe la, nutata ƒe ɖoɖoa nɔa bɔbɔe. Ganyawo ƒe bɔbɔ eye wòsɔ na ɖeka piece production of castings.

- T he dɔwɔƒe ƒe nɔnɔme le welding platform. Dɔwɔƒe si sɔ na amadede vovovo siwo tsi tre ɖe ke ŋu la toa vovo. Eyata ne ame le tiatia wɔm la, ele be wòase dɔwɔwɔ ƒe nɔnɔme si le welded flat plate la gɔme.

- Mehiã be woatsɔ primer kple topcoat asɔ kple wo nɔewo o. Welding flat plate, tsɔ kpe ɖe primer ŋu. Eye ehiã be woatae ɖe etame. Wozãa topcoats akpa gãtɔ le mɔ̃ɖaŋununya ƒe dɔwɔwɔ vɔ megbe, eyata ele be woabu alesi wotsɔa primer kple topcoat la blaa woe ŋu. Zi geɖe la, wotsɔa primer kple topcoats siwo wotsɔ amadede ƒe nu mawo tɔgbe dzrana la sɔna kple wo nɔewo. Ðewohĩ gɔmedzenuwo kple topcoa siwo wodzra ɖo kple amadede vovovowo la mawɔ ɖeka o le woƒe adhesion sesẽ la ta. Womate ŋu awɔ ɖeka kple wo nɔewo nyuie o. Eyata ehiã be woase alesi wowɔa amadedeae gɔme.

- Anti-Rust Primer ƒe xɔtutumɔnu. Anti-Rust primer ɖesiaɖe kple eƒe xɔtutu kple nutrenu nyui aɖe. Be woaɖo kpe edzi nenye be nɔnɔme mawo le dɔwɔƒea alo dɔwɔƒea la, wowɔa welded flat plate la le JB/T7974-99 ƒe dzidzenu nu. Wowɔa nusi wowɔ la wòzua ribbed plate kple box type. Mo si le dɔ wɔm la ƒe nɔnɔme le dzogoe ene me, si wotsɔ HT200 nu wɔ. Mo si le dɔ wɔm la xɔa scraping kple grinding mɔ̃ɖaŋununya, eye woate ŋu atsɔ mɔ̃ awɔ V-nɔnɔme aɖe le mo si le dɔ wɔm la dzi. T-nɔnɔme. U-nɔnɔme ƒe dowo kple do siwo le dzogoe ene me. Long holes, etc. Welding flat plate nye dɔwɔnu gbadza si wozãna na dɔwɔwɔ ƒe welding, eye ele be woatrɔ asi le agbalẽ gbadza la ŋu wòasɔ ɖe tsia dzi le ɖoɖo si hiã la nu. Womaa agbaa sɔsɔe ɖe kpekpeɖeŋunaƒe ɖesiaɖe dzi. Ne wozãe le yame ƒe dzoxɔxɔ si nye 20 ± 5 °C me la, ele be woaƒo asa na ʋuʋudedi.

Adzɔnuwo ŋuti nyatakaka tsitotsito ƒe nɔnɔmetata .

Related PRODUCTS