Welding workbench nye dɔwɔnu vevi aɖe na amesiame si kpɔ gome le welding me, si naa viɖe geɖe siwo nana dɔwɔwɔ nyuie kple dedienɔnɔ siaa nyona ɖe edzi. Viɖe ɖedzesi siwo le welding workbench ŋu dometɔ ɖekae nye eƒe liƒo. Ga si wotsɔ wɔa gayibɔ ƒe kplɔ̃ si wotsɔ dzraa gayibɔe la ɖea vi ŋutɔ le gayibɔ si wotsɔ wɔe ƒe ŋusẽ si le dzɔdzɔme nu kple esi nɔa anyi didina ta. Dɔwɔƒe sia ƒomevi ate ŋu anɔ te ɖe dzoxɔxɔ kple ŋusẽkpɔɖeamedzi sesẽ si do ƒome kple welding nu, si wɔe be wònye gadede ɣeyiɣi didi aɖe na dɔnyala bibiwo. Tsɔ kpe ɖe eŋu la, gayibɔ si wotsɔ ƒo ƒui la te ŋu nɔa te ɖe warping kple deformation nu ŋutɔ, si le vevie ŋutɔ be woalé dzogoe kple dzidzedze siwo sɔ pɛpɛpɛ me ɖe asi le welding dɔ sesẽwo me. Eɖanye be èle dɔ wɔm kple akpa siwo gɔme sese sesẽ alo xɔ gãwo o, gɔmeɖoanyi sesẽ si wotsɔ gayibɔ ƒe xɔtutu kplɔ̃ si wotsɔ dzrae na la naa kpɔa egbɔ be dɔwɔnua gakpɔtɔ li ke, si le vevie ŋutɔ na weldawo ƒe nyonyome.

Le amesiwo le gazazã dzi gome la, welding kplɔ̃ si ƒe asi bɔbɔ la naa mɔnu bubu si ŋu asixɔxɔ le evɔ wometsɔa nyonyome saa vɔe o. Togbɔ be nusi wotsɔ wɔe ate ŋu ato vovo tso tiatia deŋgɔwo gbɔ hã la, kplɔ̃ si dzi wotsɔa nu ƒoa nui si mexɔ asi o ate ŋu ana nu veviwo abe kɔkɔme si woate ŋu atrɔ asi le, anyigba si dzi woate ŋu atrɔ asi le, kple alesi woawɔ ɖeka kple klatsa kple nusiwo wotsɔna blaa nu vovovowoe ene kokoko. Kplɔ̃ siawo sɔ nyuie na modzakaɖelawo, dɔwɔƒe suewo, alo welders siwo dzea egɔme teti koe nye amesiwo hiã anyigba si dzi woate ŋu aka ɖo si ƒe asi gã aɖeke mele wo ŋu o. Mlɔeba la, eɖanye be ètia gayibɔ welding kplɔ̃ si woatsɔ adzra alo cheap welding kplɔ̃ o, tiatia eveawo siaa doa wò dɔwɔƒe ɖe ŋgɔ to nuwɔwɔ pɛpɛpɛ, dedienɔnɔ, kple welding bliboa ƒe nuteƒekpɔkpɔ me. Ne wowɔ dɔ nyuie la, welders ate ŋu awu dɔwo nu kabakaba wu, eye nu nyuiwo ado tso eme, eye dedienɔnɔ ƒe afɔku ʋɛ aɖewo koe le eme.

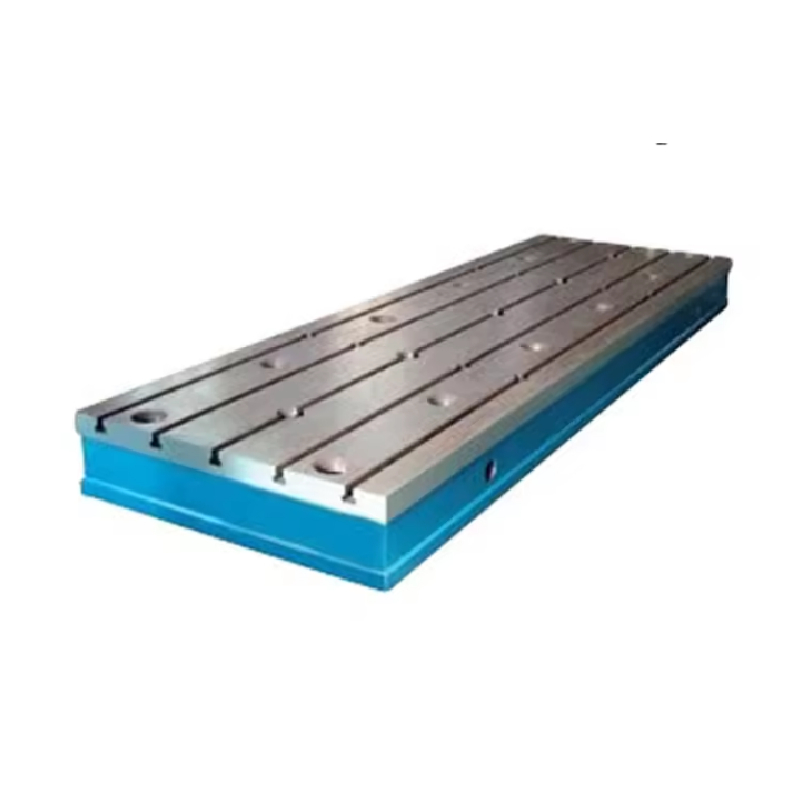

Welding Workbench Features .

Xɔtuɖaŋu sesẽ .

Kpeɖodzinu sesẽ aɖe le vevie ŋutɔ be woate ŋu anɔ te ɖe dzoxɔxɔ kple ŋusẽkpɔɖeamedzi si nu sẽ si do ƒome kple welding la nu. Nusiwo wotsɔ wɔa gayibɔ, gakpo, alo kpe siwo wotsɔ wɔa nu kpekpewoe nyea nusiwo nɔa anyi didina le mɔ tɔxɛ aɖe nu. Ga si wotsɔ wɔa gayibɔ ƒe kplɔ̃ si wotsɔ dzraa gae la naa viɖe bubu si nye dzoxɔxɔ ƒe tsitretsitsi kple eƒe liƒo, si kpɔa egbɔ be dɔwɔƒea matrɔ alo abɔbɔ le ɣeyiɣi aɖe megbe o.

Dzoxɔxɔ ƒe tsitretsitsi .

Esi wònye be welding lɔ dzoxɔxɔ gã ɖe eme ta la, ele be welding workbench nate ŋu anɔ te ɖe dzoxɔxɔ nu be wòaxe mɔ ɖe nu gbegblẽ nu. Dɔwɔƒe geɖe va kple anyigba si ŋu dzoxɔxɔ le alo esi me dzo mele o si ate ŋu ado dzi le dzoxɔxɔ si gbɔ eme evɔ womatrɔ asi le eŋu o. Nɔnɔme sia le vevie ŋutɔ na dedienɔnɔ kple agbenɔƒe didi, vevietɔ ne wole dɔ wɔm le dɔ gãwo ŋu kple ɣeyiɣi didi siwo woatsɔ awɔ woe.

Kɔkɔme si woate ŋu atrɔ asi le .

Dɔwɔkplɔ̃ si woate ŋu azã le mɔ vovovowo nu si ƒe kɔkɔme woate ŋu atrɔ asi le la wɔnɛ be nàte ŋu atrɔ asi le wò dɔwɔƒea ŋu wòasɔ ɖe dɔ vovovowo alo xɔtutu ƒe nɔƒewo nu. Esia ɖea teteɖeanyi ɖe wò ŋutilã dzi dzi kpɔtɔna eye wònaa ergonomics nyona wu na welders siwo ƒe kɔkɔme le vovovo.

Klam kple nusiwo wotsɔna ƒoa nuwoe siwo wotsɔ wɔ ɖekae .

Do siwo do ŋgɔ, ʋuƒo siwo wotsɔna ƒoa nu, alo clamp-mɔ̃ siwo wotsɔ wɔ ɖekae be woatsɔ akpɔ dɔwɔnu siwo le teƒea la le wo ŋu. Nɔnɔme sia kpɔa egbɔ be nusiwo wotsɔ wɔe la nɔa anyi le welding me, si wɔnɛ be wowɔa weld siwo sɔ pɛpɛpɛ wu.

Nudzraɖoƒe ƒe tiatiawɔblɔɖewo .

Zi geɖe la, nudzraɖoƒe ƒe dɔwɔƒe nyui aɖe si wotu ɖe eme la nyea nudzraɖoƒe si wotu ɖe eme na dɔwɔnuwo, kpeɖeŋutɔwo, kple nusiwo wozãna tsɔ wɔa nu, abe elektrikŋusẽnamɔ̃wo alo dedienɔnɔ ŋuti dɔwɔnuwo ene. Esia nana nusianu nɔa ɖoɖo nu eye wòsua ame si, si nana dɔwɔwɔ nyuie dzina ɖe edzi.

ƲUƲU ƑE NUÐEÐEŊU .

Le asitelefon dzi welding dɔwo alo fiase suewo gome la, Portability nye nu vevi aɖe. Workbench aɖewo naa afɔ alo tasiaɖamfɔ siwo woate ŋu abla, si wɔnɛ be woate ŋu aʋuʋu dɔwɔƒea bɔbɔe alo adzrae ɖo ne womele ezãm o.

lolome kple anyigba ƒe lolome .

Ele be dɔwɔƒea ƒe lolome nasɔ gbɔ na welding dɔ si ƒomevi nèwɔna. Dɔwɔƒe si lolo wu naa teƒe geɖe mí be woatsɔ akpɔ dɔwɔnu gãwo alo akpa vovovowo gbɔ, esime kplɔ̃ si ƒe asi bɔbɔ si mexɔ asi o ate ŋu asɔ wu na dɔ suewo alo teƒe si seɖoƒe li na.

Ðe gayibɔ si wotsɔ wɔe la nyo na kplɔ̃ si wotsɔ ƒoa nuwoea?

Wonya kplɔ̃ siwo wotsɔ gayibɔ wɔ si wotsɔ wɔa gayibɔe la ɖe woƒe nɔnɔme tɔxɛ si nɔa anyi didina eye woli ke ta. Ga si wotsɔ ƒo ƒui ƒe kpekpeme kpekpe kpena ɖe ame ŋu wòxɔa ʋuʋudedi le welding la me, si wɔnɛ be wowɔa dɔ le teƒe si mewɔa dɔ nyuie o. Nɔnɔme sia le vevie ŋutɔ be woalé alesi woawɔ nu pɛpɛpɛe me léle ɖe asi, weldwo ƒe nyonyome dodo ɖe ŋgɔ, kple afɔku si le warping me dzi ɖeɖe kpɔtɔ. Tsɔ kpe ɖe eŋu la, gayibɔ si wotsɔ ƒo ƒui ate ŋu anɔ te ɖe dzoxɔxɔ gãwo nu, si ana wòasɔ na welding dɔ siwo wowɔna edziedzi kple wo wɔwɔ vevie siaa.

Viɖe bubu si le gayibɔ si wotsɔ ƒoa gae ƒe kplɔ̃ ŋue nye alesi wòtsia tre ɖe nɔnɔmetɔtrɔ ŋu. To vovo na nusiwo me kɔ wu la, gayibɔ si wotsɔ ƒoa gae ƒe kplɔ̃ si wotsɔa gayibɔ wɔe la léa eƒe nɔnɔme ɖe te le nuteɖeamedzi me, le ezazã ɣeyiɣi didi gɔ̃ hã me. Tetenɔnɔ ɖe nɔnɔme sesẽwo nu sia wɔnɛ be welders te ŋu wɔa dɔ kple kakaɖedzi evɔ wometsi dzi ɖe kplɔ̃a ƒe fɔmaɖimaɖi ŋu le ɣeyiɣi aɖe megbe o.

Le amesiwo di be yewoade ga asi na gayibɔ si wotsɔ ƒoa gae ƒe kplɔ̃ si wotsɔ gayibɔ wɔe gome la, woate ŋu adzra tiatia geɖe. Ga si wotsɔ wɔa gayibɔ ƒe kplɔ̃ si wotsɔ dzraa gae ate ŋu ana egbɔkpɔnu deblibo na modzakaɖelawo kple welders siwo nye dɔwɔla bibiwo siaa. Zi geɖe la, nudzralawo naa lolome kple ɖoɖo vovovowo be woakpɔ welding ƒe hiahiã tɔxɛwo gbɔ, wowɔa dɔ na dɔwɔƒe suewo kple dɔwɔƒe gãwo siaa.

Le nyataƒoƒo me la, gayibɔ welding kplɔ̃ si wotsɔ gayibɔ wɔe nye ga si me nunya le na amesiame si tsɔ ɖe le welding me vevie. Alesi wònɔa anyi didina, eƒe liƒo, kple tsitretsitsi ɖe warping ŋu na wònye tiatia nyui aɖe si ana nàkpɔ emetsonu deŋgɔwo. Ne èle ŋugble dem le welding table ƒeƒle ŋu la, gayibɔ ƒe tiatia siwo wowɔ la me dzodzro ate ŋu ana nàwɔ dɔ nyuie wu eye nàkpɔ dzidzeme le wò welding dɔwo me.